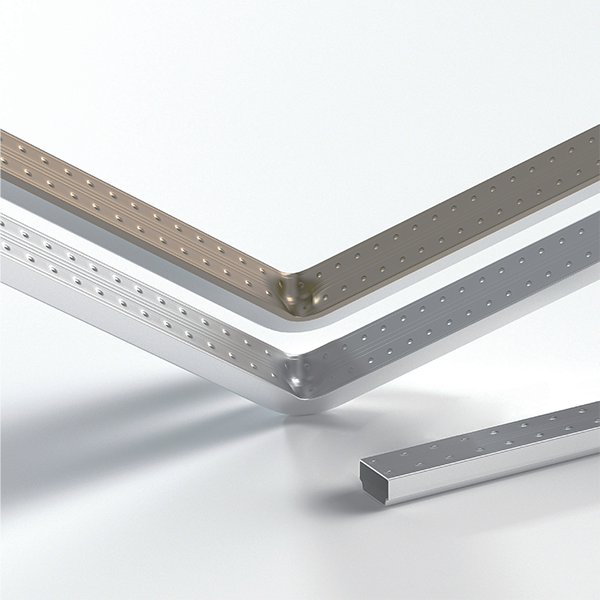

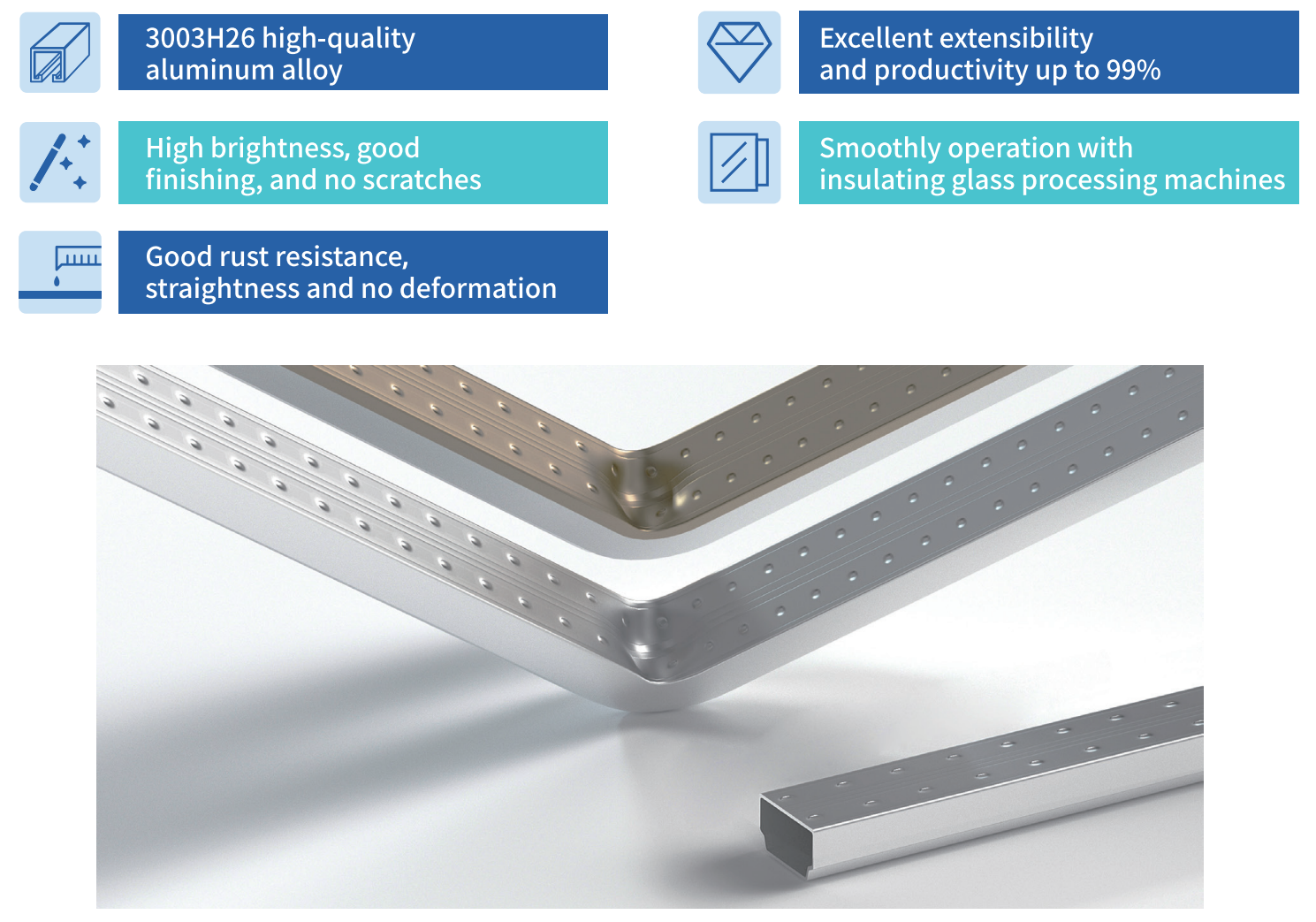

It is designed with perfect bending performance for insulating glass.Thewelding line is seamless with no scratches,which kept the integrity of thealuminum strips.In the other hand,it improves the ability of resistance tooxidation with shining surface.The unique technique welds the aluminumstrips together tightly so that the insulating glass would have the bettersealing effects.Stronger welding can also minimize the possibility of argon gasleakage,which will also prolong the shelf life of insulating glass unit.Thanks tothe smooth welding in the back,the operation to automatic butyl sealantextruder and spacer bending machine will be more convenient and efficientlywith less wastes and higher rate of finished products.

+381 604 414 811

+381 604 414 811 sales@glassmatgroup.com

sales@glassmatgroup.com  Home

Home Products

Products Telephone

Telephone WhatsApp

WhatsApp